Plastic Granulator

Most people are aware that plastics are not currently biodegradable, and that there are great economic and environmental incentives to recycle post consumer and post industrial plastics. This can only be achieved in a profitable manner with high volumes of consumer plastics and a properly designed plastic shredding and granulating system. Jordan Reduction Solutions offers a wide line of industrial granulators suited to meet your plastic reduction application needs when it comes to recyling post consumer plastic such as water bottles and the like, to recycling post industrial plastic such as extrusion scrap or off spec parts.

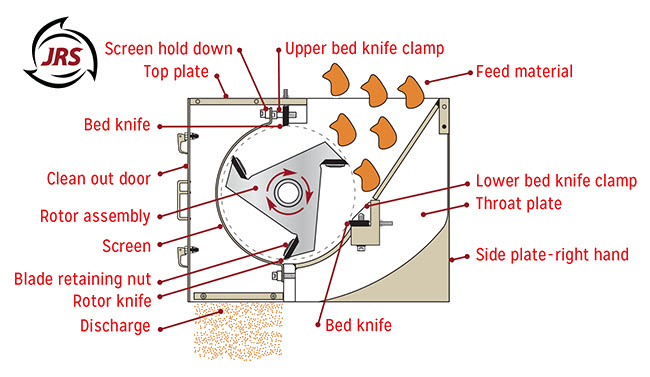

Open Rotor Granulators

Our rugged and reliable open rotor granulators have been designed and constructed using the the toughest components available. From various fabricated base designs to solid forged rotors, all of Jordan’s granulators and component parts are engineered and constructed to meet your toughest applications. With long term reliability and world class support we can fulfill your application needs whether that need is an organics granulator, a plastics granulator or other a unit for other applicable materials.

Design and Options

Designed for high-speed and medium-inertia applications, our open rotor industrial granulators are available in 3, 5, 10 or 15 blade designs dependent upon machine model and material application. These units can process a variety of materials in final reduction sizes down to 20 mesh dependent upon the material being processed.

Open rotor design industrial granulators come in a variety of feed options. We offer clam shell safety hoppers for hand feeding operations to protect your personnel from accidental rotor access; Open front, continuous conveyor feed options; sealed pneumatic feed options and many other customer hopper configurations.

We also offer customs stand options such as portable roll around units and even lab style versions for additional flexibility. Gravity and pneumatic discharge chutes are also available depending on your final discharge needs; making the JRS Granulator, one of the most customizable granulators on the market today.

Heavier duty granulators are also offered for more high capacity and tougher production needs, so tell us your application needs today and find out which JRS granulator is best for your demanding application.

Granulator Sizes

- Chambers from 10″ x 12″ inch up to 22″ x 60″ inch

- Motor sizes from 10HP to 250HP

Granulator Parts and Service

With an extensive inventory and a complete line of CNC Machine Centers, we can supply your parts quickly – often overnight. We stock knives, bed knives, screens and additional components. Learn more about our Parts and Service Department.